When it comes to homebuilding and home improvement, selecting the proper materials for the labors at hand can be the deciding factor. Durock – Popular with Pros and Those Budgeting for the Future Durock (another brand I’ve used many times) is a durable, versatile cement board suitable for both indoor and outdoor tile applications. Whether installing tile, stone or brick, Durock provides a reliable, water-resistant tile backerboard that allows you to build a strong, long-lasting foundation that won’t decay. However, what is Durock exactly and is it the ideal material for your next project? This guide will walk you through everything you need to know, from types and uses to installation and the costs.

Thank you for reading this post, don't forget to subscribe!What Is Durock and Why Is It Applied?

Durock is a brand of cement backerboard made of aggregated Portland cement, with fiberglass mesh on the surfaces for water resistance. It’s made to be an attractive and water-resistant surface, one that you might find in a bathroom or kitchen.

Because it is not susceptible to warping and won’t grow mold, Durock stands up better against establishment than drywall or even plywood. These properties make it perfect for applications that need both tear resistance and durability over time.

Types of Durock

To help you make a more informed decision, here’s a guide to the different types of Durock.

Cement Board

This is what most people think of when you mention Durock which is essentially a cement board made of Portland cement with a non-absorbent core and a glass fiber mat that is wound tightly towards the edges. It is commonly used as a tile backer and is highly resistant to water exposure.

Tile Backer

Tile backer boards are made especially to to be used as your base for your tile installation. A kind of cousin of cement-board products, fiber-cement tile backer is made just for use beneath tile in wet locations.

Fire-Rated Durock

Some types of Durock boards are also fire-resistant, which can make them a great choice for projects that must adhere to building codes for fire protection.

Applications of Durock

Durock is a versatile product that can be used in many ways, it is also quite robust.

Flooring

Durock is installed in tile floors to serve as a base for ceramic, porcelain or stone tiles. It gives you a smooth, waterproof surface that protects the underlying floor.

Walls

Because of its resistance to moisture, Durock is often used for bathroom and laundry room walls as a backing for tiles and other finishes.

Countertops

Durock is an excellent base for DIYers building custom countertops. It’s durable and water-resistant properties mean it’s perfect for kitchen countertops.

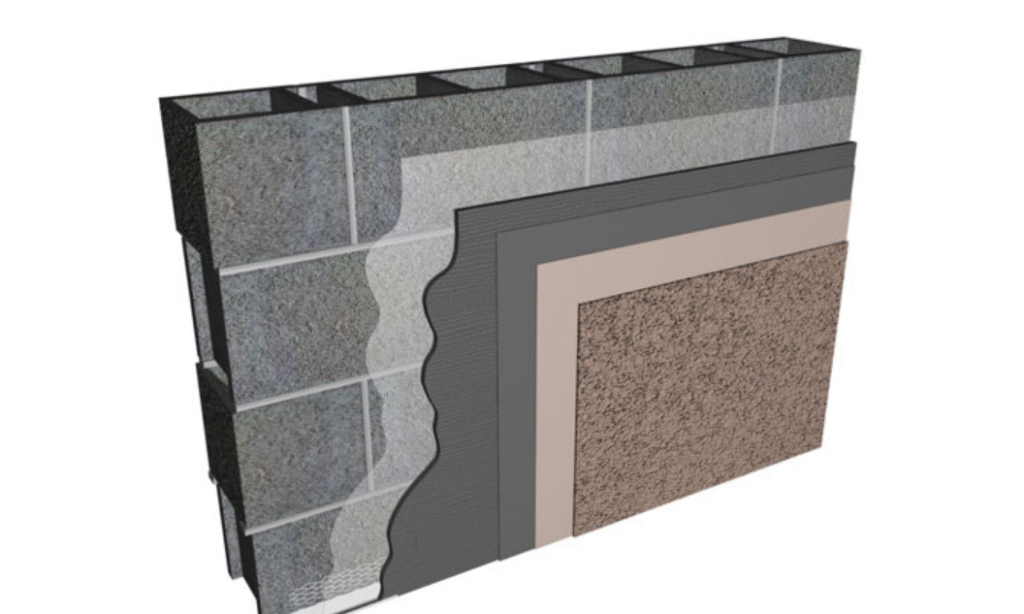

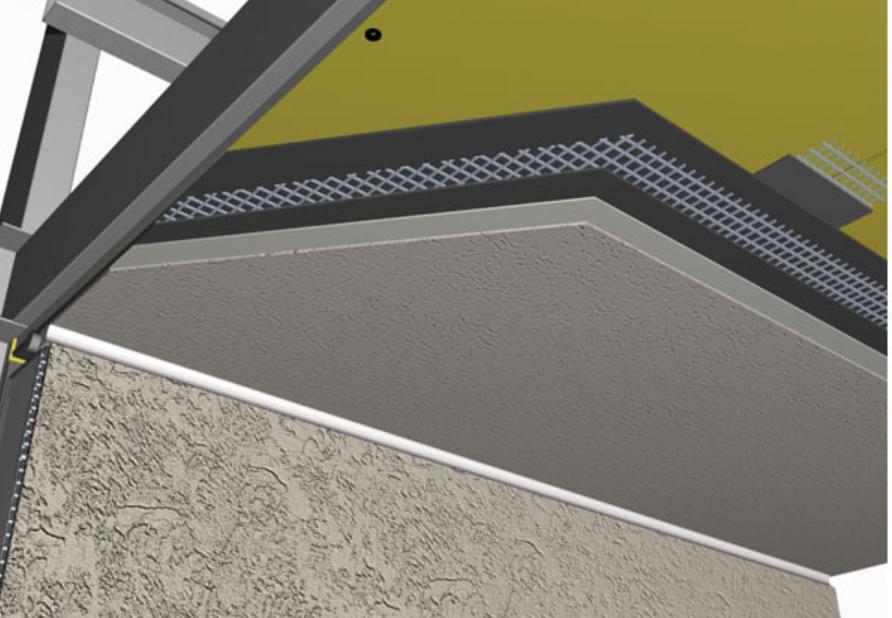

Exterior Facades

Some types of Durock can be installed on the exterior of a building as a decorative facade or siding due to its weather resistant properties.

Pros and Cons of Using Durock

Before going all out on Durock, you might want to consider whether the benefits outweigh the drawbacks.

Pros

- Sturdy: Restrains no water, no alertness and no endless impacts.

- Versatile: For use as flooring, walls, and other surfaces.

- Fire-Proof: A few types are incredibly fire resistant.

- Durable: Perfect for permanent mounting.

Cons

- Heavy: Durock boards weigh more than other options, such as drywall.

- Cuts are dirty: Durock board will create dust and dirt around you while you are cutting it.

- Rigid: This will not be easy to apply on a curve or rounded area.

Installation Guide for Durock

There is a process to follow to properly install Durock. Follow these simple steps:

Surfacing: Make sure foundation is clean, dry and level.

Measure and Cut: Measure your space and cut the board with a utility knife or saw.

Put down the Board: Place Durock on the surface and fasten it in place using screws or nails, and make sure to leave space between boards to prevent buckling.

Tape Joints: Tape all seams with alkali-resistant fiberglass tape.

Edges- Joint Sealing: The joints should be properly sealed by filling them with thin-set mortar or adhesive.

Items which are Required for installation

Here’s what you need to get started:

- Tape measure

- Utility knife or circular saw

- Drill with concrete board screws.

- Alkali-resistant fiberglass tape is another alternative.

- Mortal or an adhesive to set the tiles

- Trowel or putty knife

- Dust mask and safety goggles

Tips for Working With Durock

Use the Appropriate Tools- Reduce the amount of dust you create by using tools that are made for the purpose of cutting cement boards.

- Handle It with Care: While Durock is strong, it is not immune from chipping on the corners if man handled.

- Pre-Drill Screw Holes: Screw holes need to be pre-drilled to prevent cracking on installation.

- Safety First: Use safety gear (a dust mask and goggles) when cutting to keep cement dust at bay.

Common Mistakes to Avoid

Avoiding Taping: Do not skip taping the joints as this can lead to weakness of the surface through the years.

Then Regular Screws Regular screws can rust; therefor, always use cement board screws.

Irregular Surfaces: Have a level surface to prevent cracks in the tiles later.

Cost Analysis of Durock

Durock is a budget friendly option, particularly for the quality. On average:

- 4×8-Foot Board: $14-$20

- Screws and Tape: Around $10

- It’s a little pricier than drywall up front, but it will last longer than you, and you’ll never feel through your lunch break while you’re sitting on it.

How to Maintain and take Care of Durock

Indeed, after the installation, Durock needs very little looking-after:

- Frequently clean: Gently wipe surface of the screen with a wet cloth, so as not to absorb water.

- Examine for Wear: Inspect for signs of cracks or damage in high-moisture environments.

- Re-seal Joints: Re-apply fresh mortar or tape to insure joints remain waterproof.

Durock vs. Alternatives

Durock vs. Drywall

- Moisture Resistance: Heavy advantage for Durock.

- Cost: Drywall is more affordable, but not as long-lasting.

Durock vs. HardieBacker

- Weight: HardieBacker is less weighty and easy to handle.

- Ruggedness: Durock is a bit better-equipped to resist mold and mildew.

Case Studies

-

Modern Bathroom Renovation

A Durock substrate was used by a homeowner to back their large-format bathroom tiles. The outcome? A perfect water proof finish that lasted years.

-

Durable Kitchen Countertops

One DIYer built a custom tiled counter on Durock. They raved about its strength and stability when it came to holding heavy granite tiles.

FAQs About Durock

How thick does Durock need to be for floors?

Tile underlayment on floors should be 1/4 inch minimum.

Is Durock waterproof?

Though resistant to water, Durock is not waterproof by itself. Pair it with other waterproofing, if you need to.

Can Durock be used outdoors?

Yes, but make sure it’s of the kind that is meant to be outdoors.

Will It Work for You?

View in gallery Ideal for tiled bathrooms and kitchens and for strengthening walls You can be sure that, whether you are going for a tiled bathroom, a kitchen counter or simply reinforcing walls, Durock is the perfect material. And it is a favorite amongdo-it-yourselfers as well!

If you’re looking to give Durock a go, follow our step-by-step process to make sure you do the job right.